Double Edge Razor Blades, or DE Razor Blades, are a popular choice for many Barber Supply and Bakeries workshop or companies.

Xirui manufacturing Double Edge Razor Blades are always made of Premium Quality Stainless Steel(eg. SANDVIK Steel) and individually wrapped. Our razor blades are made very thin to create a sharp edge for close shaves or precise cuts, and can be used in any standard safety razor or fitted onto a Baker’s Lame.

Feature Highlights

- Thin and with sharping edge performance.

- Made with high quality stainless steel.

- Used in many industrial, eg. barber, baker and industrial usage.

- Coated options, coated with Teflon & Chrome coating to give a more smooth shave performance.

Why Choose Xirui

- The leading razor blade manufacturer from China.

- Production Capacity, our monthly capacity up to 100 million pieces of razor blades.

- End to end solution, support customize OEM/ODM manufacturing.

- Decent technology and latest equipments, manufactures precise and quality blades suitable for each purpose to meet your demand.

Note: Our product only available for B2B wholesale and OEM/ODM, Contact for OEM/ODM

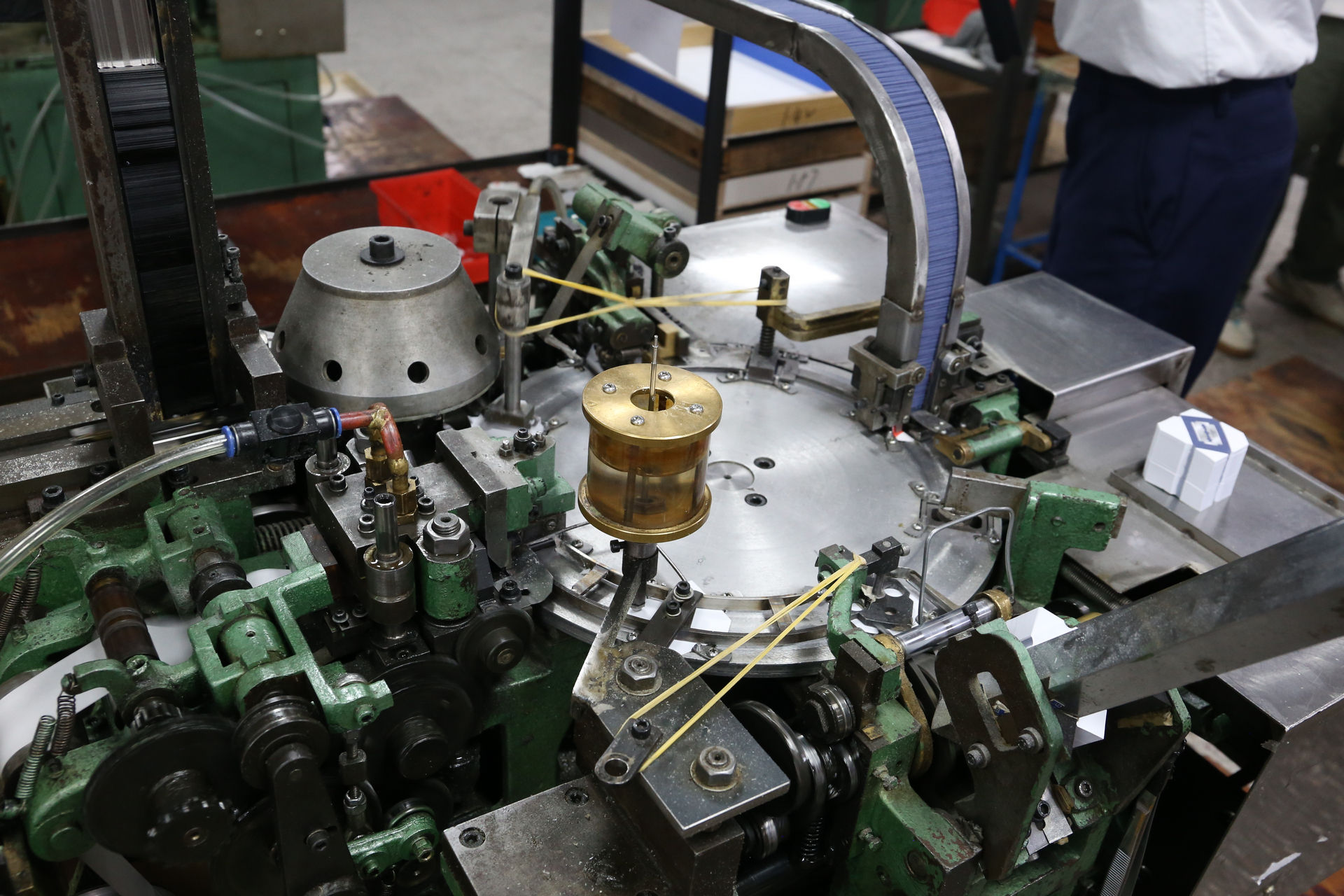

Production Process

- Press Process

- Heat treatment

- Logo oil printing(optional)

- Blade edging and polishing

- Blade edge inspection and testing

- Coating Process

- Sample quality inspection and testing

- Packaging

Read our blog that detailed explain: How double edge razor are made.

Automate Package System

Full production line in our xirui factory

Specification

Our double edge razor blades products are made only for wholesale, OEM and ODM. If you represent your company, you could easily contact us for free sample, product category and custom manufacturing.

| Product Image | Product No. | Materials | Specification |

|---|---|---|---|

| XR-B074 | Stainless Steel available for customization | 42.6x22x0.1mm |

Faq

What's the type coating that your razor blade coated with?

Our xirui made safety razor blades coated with different polymers made of chromium, tungsten and more are used to benefit the user – yourself, in your needs.

Different coatings have different minor effects, but overall, the purpose of the coating on our razor blades is to increase and prolong the sharpness, and subsequently adding to your customers’ satisfaction with the shave it delivers.

Currently, The types of coating we supported

- Chromium

- Teflon

Note: Platinum, Tungsten coating are not support by our factory

How your factory manufacturing performed so far and how will it perform in the coming years?

With the overall increase in the demand for men’s grooming products, especially in the market of the shave care products, Xirui has take this chance and grows rapidly in recent years.

Currently, our factory manufacturing in 24-hour workday with three-shift system to meet our clients’ production needs, our monthly production capacity is up to 100 million pieces of razor blades. And we believe there is still a high potential for growth in this market and industry.

Feel free to contact us if you have any questions regarding our double edge razor blades.